I’ve gained a lot of respect for (and interest in) the power of 3D printing custom car parts after chatting with a 3D designer. Today, another really cool perspective on this style of manufacturing came across my desk—a video documenting the engineering of, as well as the fine-tuning of, custom turbo plumbing with parts that are 3D printed out of steel. The kicker is, the parts cost a lot less money than you might expect.

Jon Volk is known in the custom BMW community for making exhaust manifolds that people attach turbos to and make big power with. You’ll see his name pop up in plenty of old forum threads on E30 and E36 tuning, especially. Lately, you’ll find him doing more with digital part engineering and 3D printing on his YouTube channel Couch Built where he’s “Building cars, mostly from the couch, with use of 3D scanning, Fusion360, and some bloody knuckles sprinkled in.” He’s the guy behind the 13B rotary-powered BMW i8 project we wrote about earlier this year.

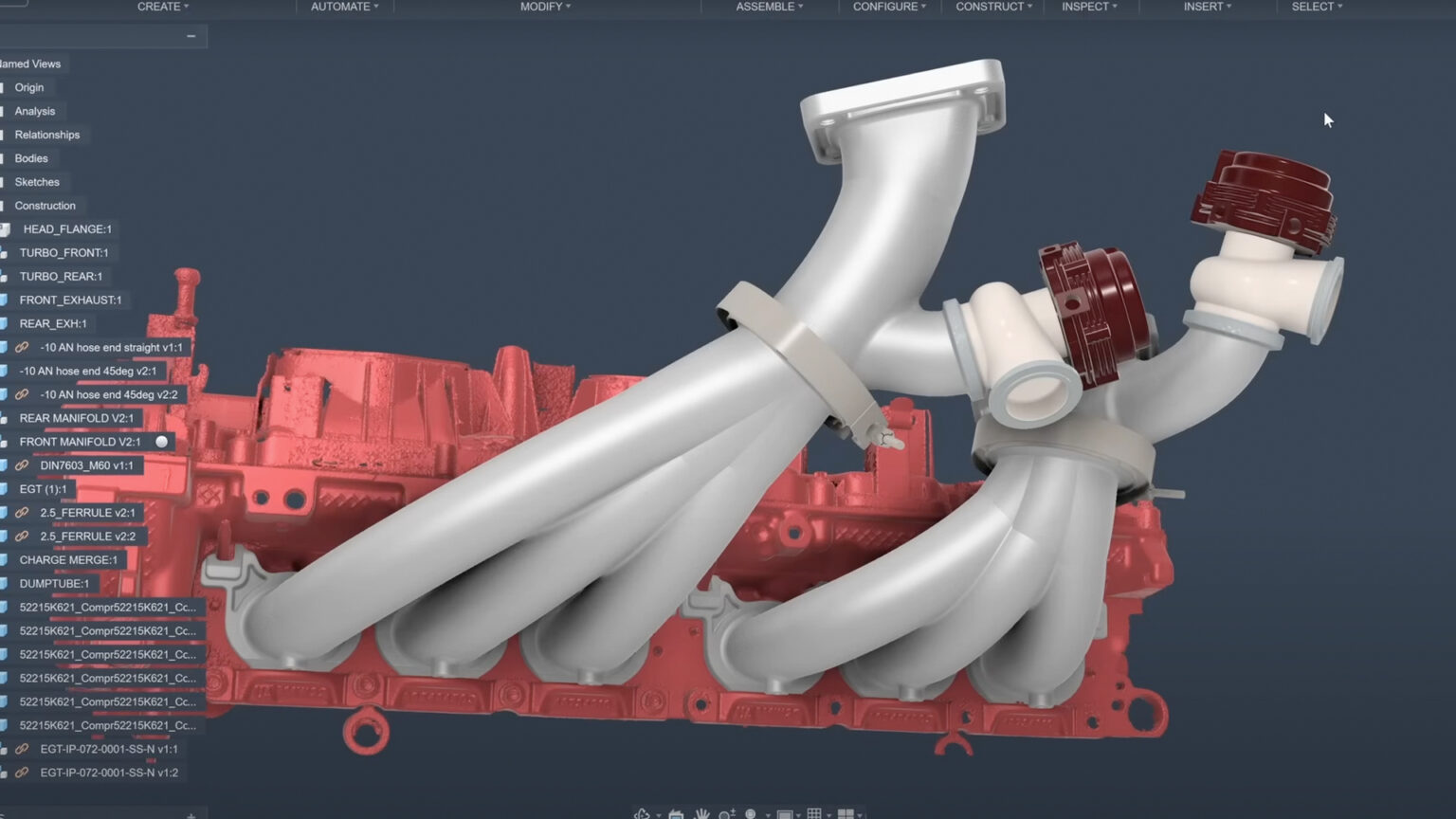

In a new video he uploaded, he walks us through the process of designing a new exhaust manifold for an absolutely insane G80 BMW M3—a 1,000-plus horsepower monster owned by Jordan Horowitz. He’s also a big Bimmer modder with a shop called RK Tunes on Long Island.

I was initially intrigued by this video because of the “it’s cheaper than you thought” aspect of the title, but I got sucked in watching Volk showcase how he optimized the exhaust manifold design and general plumbing of the turbo kit on his computer. It’s really neat to see the project come together.

Volk explains how things are laid out and tweaked virtually, and then instead of sending plans to a fabricator like somebody might have done a few years ago, he simply sends his designs to a 3D printing company and gets them quoted. In this case, he’s sponsored by JLC3DP, which 3D prints everything he mocked up for about $2,200. That’s not a plastic mock-up piece, that’s a real, steel, turbo kit (minus the turbo) that’s nearly ready for installation when it arrives in the mail.

That’s comparable to the price of a high-quality performance header a decade ago. But don’t get too excited, that price excludes a critical factor—Volk’s time and expertise. The parts were only $2,200 once he knew what shape they had to be. If you need to pay somebody to do the design, that’ll be a much bigger portion of your modding budget. At least, until AI can design an exhaust manifold (probably the not-too-distant future, honestly).

Still, that’s less money than you’d have spent on the fabrication of something like this in the past. And just the fact that this kind of single-unit manufacturing is available is pretty amazing.

Check out the video of the design, take a look at what Volk had to do to clean up the part once it showed up. The clip will give you a sense of the current state of high-end exhaust tuning.

Horowitz also uploaded a video about the part, which you can check out for even more context if you want to go deeper:

I have so much respect for the engineers and tuners who can dial in stuff like this. I’m just happy if I can keep mice from eating my stock E46.

Got a tip? Drop us a line at tips@thedrive.com

Read the full article here