Manual gearboxes are pretty simple. I remember my high school physics teacher diagramming one on the chalkboard: power goes in on one shaft, goes through a couple of wheelie-looking things, and boom, comes out on another. Easy-peasy. Things get a little murkier with an automatic. There’s still power going in via a big metal stick, but it must first navigate a marble maze to find the proper exit before getting strained through a magical garbage disposal that somehow turns it all back to power going through a shaft again. Wee, science!

CVTs sort of split the difference. A typical automotive CVT utilizes two conical pulleys with a belt or chain that moves in and out to adjust its output ratio. Even among enthusiasts who cannot articulate precisely how that process works, there’s one fundamental fact we all know: CVTs don’t have gears. Right?

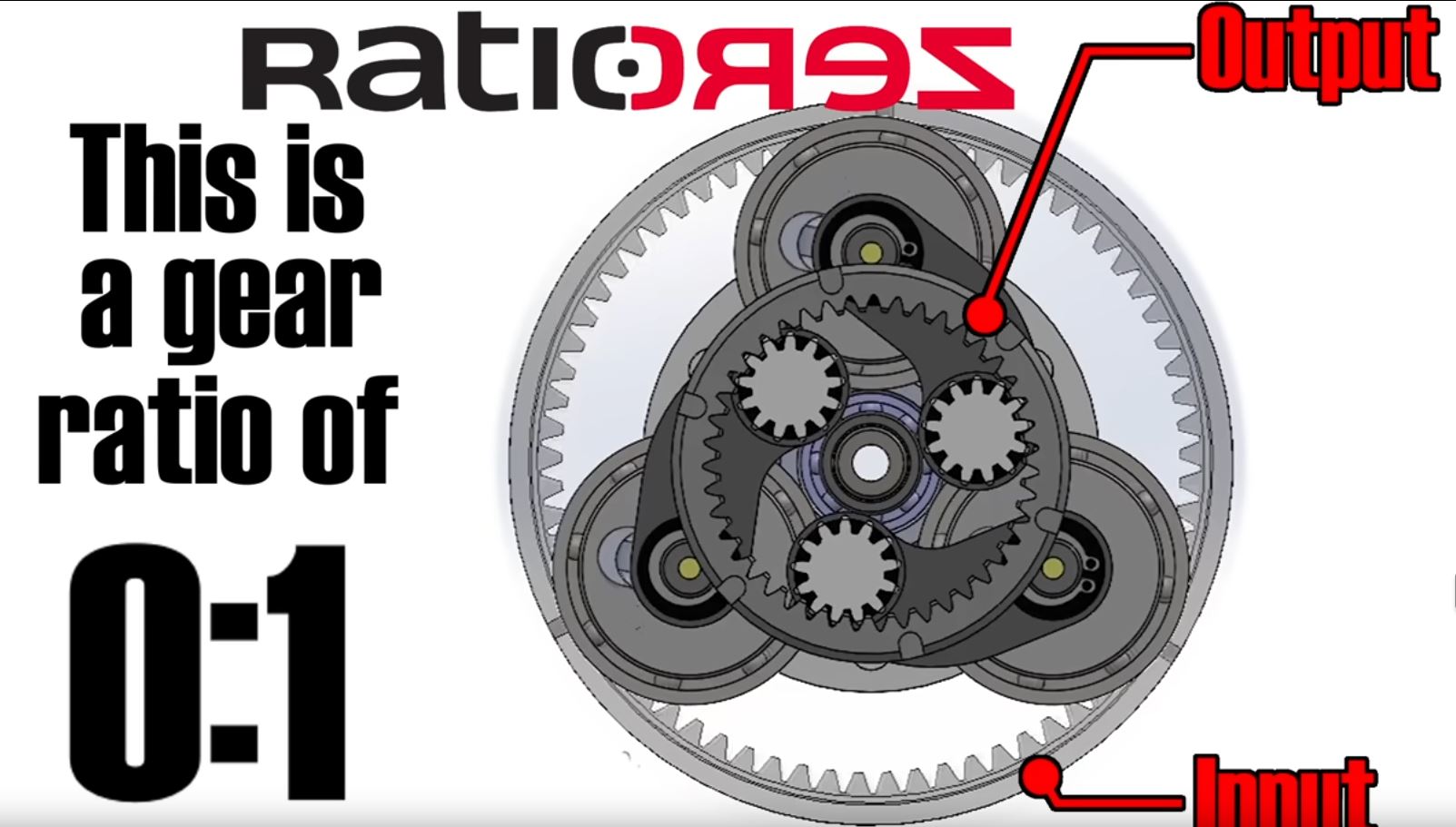

That sort of thing puts you in the realm of planetary gearboxes. They already exist in the automotive marketplace—look no further than most Toyota hybrids, for instance—but they’re not really CVTs as we conventionally define them. And now there’s a third contender: a geared CVT that utilizes a new layout entirely. Invented by a team of engineers in Italy, it’s called the “Ratio Zero” transmission; let’s call it the RZT for short.

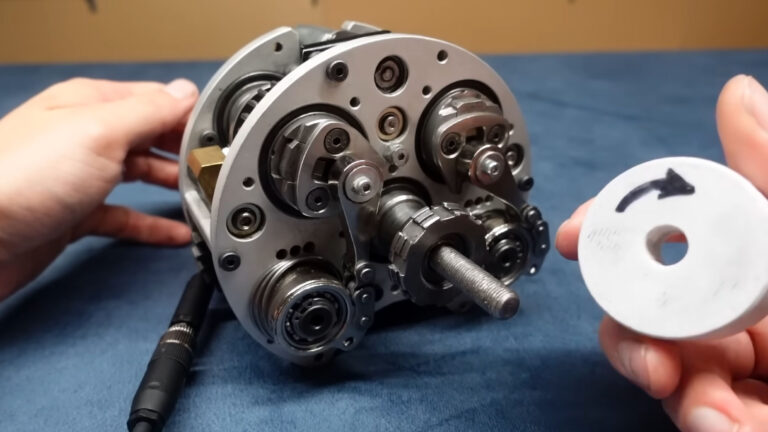

If you need a refresher on the mechanics of an automotive gearbox, the first two segments are worth a quick watch. If you’re already familiar, skip ahead to the 8-minute mark for a description of the design itself, which uses three planetary gears mounted on adjustable arms to translate the input power from the outer ring into rotational force on the central output shaft.

We won’t get into the nitty-gritty, but the RZT prototype addresses the key issue with a conventional CVT: that it can only handle so much torque before its belt or chain slips. With a geared setup, the torque tolerances go way up. The switch from friction-based power transfer to mechanical power transfer also significantly improves the efficiency of power transfer, as far less energy is being bled away as heat. But the RZT’s real party piece is the fact that its output ratio is not only infinite, it can actually be zero. Meaning the transmission itself can effectively idle without the use of a clutch or torque converter.

This compact prototype is intended for extremely low-torque applications (think e-bikes), but the concept was designed to scale up to larger vehicles, including motorcycles and automobiles, which would need to put a lot more torque through those small “relay” gears. It’s a cool design with a lot of promise, but whether it can be made practical for automotive applications remains to be seen. Color us intrigued.

Got tips? Send ’em to [email protected]

Read the full article here